Introduction

The Department for Infrastructure (DfI, the Department) has responsibility for the road network in Northern Ireland. Under Article 8 of the Roads (Northern Ireland) Order 1993, the Department has a statutory duty to maintain the provinces road network. Analysis, Statistics and Research Branch (ASRB), a Northern Ireland Statistics and Research Agency (NISRA) branch within DfI produce and publish the ‘Northern Ireland Road Network and Conditions’. This technical report provides additional information which has not been included in the official statistics report or in the user guidance section. This technical report covers all topics (Road Length, Road Condition and Road Expenditure) for completeness but the primary focus of this report is to provide more technical information relating to the collation of the road condition data.

Road Length

Road lengths are handled and compiled at a divisional level (in the four DfI divisional Headquarters) and are recorded on RMCS. The road lengths are the digital measurement of roads presented in kilometres.

DfI divisions will receive information about new developments (i.e. housing estates) and new sections of roads etc. that are to be adopted into the public road network. This is where additions to the overall network length will occur. Sections of carriageway can be abandoned as well, thus subtracting from the network length.

From the information received at divisional level a centre line can be added onto the system to create a new section, as well as adding attributes such as new name, route number, reference numbers. This will automatically update on the client system and add that new section into the local divisions maintenance and inspection records going forward.

All road lengths from RMCS are shown in kilometres. The figures only cover adopted roads i.e. public roads which are maintained by DfI Transport and Roads Asset Management. Slip roads are not included in motorway route lengths. Operation data indicate that slip road route lengths add up to approximately 19km. Data exclude car parks and footpaths.

Urban-rural data are based on road speed limits. Urban roads are defined as having a speed limit of 40 mph (miles per hour) or less. Rural roads are defined as having a speed limit of more than 40 mph.

The locations of council boundaries do not coincide with boundaries used by DfI Transport and Roads Asset Management for motorway maintenance purposes. Therefore, the figures presented in Figure 1 for motorway road lengths by Local Government District are a close approximation.

Figures on Road Lengths are a snapshot from the Roads Maintenance Client System at 1 April in any given year and are available for Motorways, A, B, C and unclassified roads: -

- A roads - major roads intended to provide large-scale transport links within or between areas.

- B roads - roads intended to connect different areas, and to feed traffic between A roads and smaller roads on the network.

- C roads - smaller roads intended to connect together unclassified roads with A and B roads.

- Unclassified roads - local roads intended for local traffic.

Route kms is the distance between two points on the road network, regardless of whether the section is motorway or dual carriageway.

Further information relating to the quality of data from the RMCS is available from the Northern Ireland Road Network and Conditions - Quality Assurance of Administrative Data Report .

Road Condition

Measuring Road Conditions with SCANNER

SCANNER (Surface Condition Assessment for the National Network of Roads), or High Speed Road Monitor, consists of a number of laser sensors mounted on a purpose built vehicle (see picture below).

SCANNER vehicle

The SCANNER vehicle travels at close to traffic speed and measures the condition of the road in terms of the extent of surface cracking, ride quality, wheel-track rutting and alignment.

The Department has currently procured an external contractor WDM to undertake SCANNER surveys on all roads in Northern Ireland. Although SCANNER is currently carried out on U class roads to enable a comparison exercise with the Coarse Visual Inspection (CVI) survey, the information from SCANNER is not used currently used to determine condition for this class of road.

More information on SCANNER vehicles is available at this link.

SCANNER parameters and the Road Condition Index

Individual SCANNER parameters can be used to identify lengths containing particular types of defect. However, the SCANNER RCI (Road Condition Index) was developed through the SCANNER research programme to combine SCANNER defects into a single value to assist in the assessment of road condition. The RCI is the industry standard measure for road condition currently in use.

The SCANNER RCI is calculated using a sub-set of the parameters measured by SCANNER (these are referred to as the core parameters). In summary, these are:

• Maximum rut depth

• 3m Moving Average Longitudinal Profile Variance

• 10m Moving Average Longitudinal Profile Variance

• Whole carriageway cracking

• Texture depth

In order to obtain an RCI value each parameter is scored between two thresholds – a lower threshold below which there is no need to consider maintenance, and an upper threshold above which further deterioration does not increase the score.

These thresholds were based on engineers’ experience of each parameter. The score increases linearly between the lower and upper threshold from zero at the lower threshold to 100 at the higher.

The score for each parameter is then multiplied by two factors, each having a value between zero and one. One factor reflects the “relevance” or importance of the measurement to the maintenance condition of the road. The other reflects the “reliability” of the method of measurement. The result is a weighted score for each parameter for the 10m subsection. Note that, to avoid Longitudinal Profile Variance having a disproportionate effect on the reported condition, the weighted scores for 3m Moving Average Longitudinal Profile Variance and 10m Moving Average Longitudinal Profile Variance are compared, and only the largest of these two scores is taken forward to contribute to the calculation of the RCI. The same is true for rutting, with only the maximum of the offside and nearside rut depths being taken forward to the calculation of the RCI. The weighted scores are summed to give a single RCI value for each 10m subsection length, representing the overall condition. The SCANNER RCI values reported by SCANNER can be used by highway engineers (often by displaying the data on a map background in a geographic information system (GIS)) to identify lengths of the network in need of further, more detailed, investigation.

The parameters are scored against different definitions for different types of road. This is so that maintenance is prioritised for roads that are more frequently used. Users should note therefore that the proportion of ‘red’ roads is not comparable across road classes. For example, an A road categorised as red could be in identical condition to a B road categorised as amber.

Classification of SCANNER RCI figures

RCI figures are collected for the Motorway and trunk road network as well as A, B, and C Class roads and are used to identify the need for structural repairs. An RCI greater than 100 (classified as being red) indicates poor road conditions and a requirement to plan maintenance soon; an RCI between 40 and 100 (classified as being amber) suggests the road is in average condition and should be monitored; and an RCI less than 40 (classified as being green) means the road is in good condition.

Examples of roads which would fall under the green (left), amber (centre) and red (right) categories

Road classes included in SCANNER surveys

Excluding roads under Public, Private, Partnership (PPP) Contracts, SCANNER surveys are currently carried out on half of the motorway and trunk road network each year whilst B and C Class roads are surveyed at a rate of 25% each year.

Processing of the raw SCANNER data

Processing of the raw SCANNER data takes place through an accredited UK Pavement Management System (UKPMS). UKPMS compliance accreditation is monitored through the UK Roads Liaison Group (UKRLG), which brings together national and local government from across the UK to consider roads infrastructure engineering and operations matters.

Further information on the SCANNER survey

This link provides information on the national standards and their volumes as they relate to SCANNER. In particular, Volume 4 provides information in terms of what SCANNER measures which includes the Longitudinal profile, transverse profile, rutting and rut depth, texture, multiple line texture, cracking, edge deterioration etc.

This link is to DfT’s technical document in England that provides an explanation of how SCANNER is measured, the parameters involved and how data are generated and used.

Further information from DfT in relation to notes and definitions used for Road Condition Statistics is available at this link.

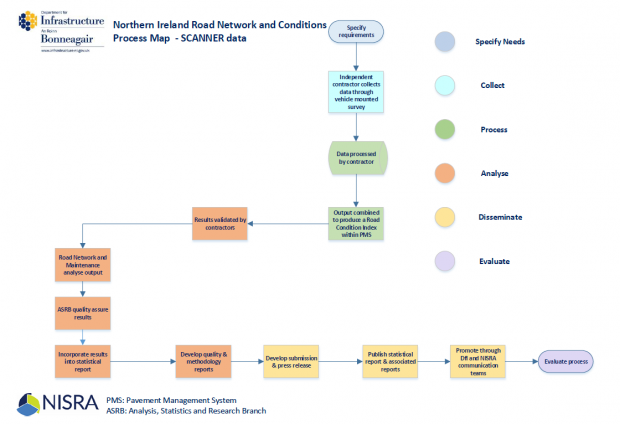

Process map of SCANNER data from collection to dissemination

A process map showing the flow of SCANNER data from collection to dissemination is available below and on the DfI website .

SCANNER figures used in bulletin

The key summary figures from SCANNER in the bulletin show the overall percentage of each network being classified as red, amber and green from SCANNER results.

Measuring Road Conditions with Deflectograph

Deflectograph surveys are carried out by a vehicle that measures the deflections of the roads surface under defined loading and uses this information to calculate the residual life of the road pavement and the need for structural repairs (see picture below).

Deflectograph vehicle

The vehicle operates at low speeds and consequently, Deflectograph surveys are relatively expensive. Currently, Deflectograph surveys are carried out on one third of the motorway, trunk and non-trunk A class road network each year.

DfI Transport and Roads Asset Management Consultancy Services (Materials Engineering and Assessment Section, MEAS) carry out the Deflectograph survey. Once the data from these surveys are collected by the survey teams on site, it is then processed in-house by the MEAS staff in the first instance; this is done via the WDM Pavement Management Software (PMS) (which MEAS staff only have access to). This process, known as fitting, is carried out by trained MEAS staff, involves raw survey data taken directly from the machine being inputted into the PMS, with checks, and balances from calibrations and seasonal factors etc. taken into account. Once the raw data have been through the first stage of processing, WDM will handle all subsequent stages thereafter, due to protocols around data safety and system integrity.

The key tables from the Deflectograph survey in the bulletin cover figures on the residual life of the trunk, motorway and combined trunk and motorway by number of years of life. These figures are summarised to show the percentage of each category of road that has a residual life of more than 5 years.

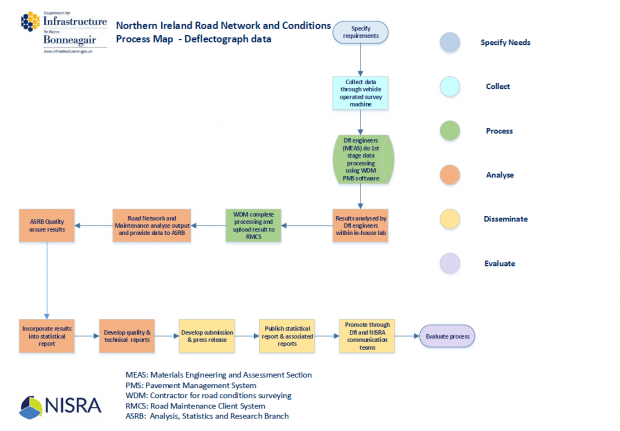

Process map of Deflectograph data from collection to dissemination

A process map showing the flow of Deflectograph data from collection to dissemination is available below and on the DfI website.

Further information on the Deflectograph

This link is to DfT’s technical document in England that provides an explanation of how Deflectograh is used to measure road condition.

Measuring Road Conditions by assessing the number of surface defects instructed and repaired.

Information on the number of surface defects is managed through the Road Maintenance Client System (RMCS) a mapping based data management system. This is a live system where data are updating all the time.

Road engineers inspect the roads for surface defects. The engineers use a hand held device (tough book) linked to the RMCS to record surface defects. The details of the surface defects are recorded by the engineer; surface defects are recorded using a range of defect categories, e.g. pothole, rutted, depressed, cracked, uneven, etc.

The defect is also prioritised dependant on severity and risk to the public according to the following classification: -

- R 0 – Repair or make safe as soon as practical

- R 1 – Repair or make safe before the end of the next calendar day

- R 2 – Repair or make safe within 5 working days

- R 3 – Only Defects on low traffic, rural roads and medium and low traffic (high risk) footways to be repaired within 4 weeks

- R 4 – Repair during the next available programme or by target response time as specified, or review condition at next inspection

There are some R3 defects that are not included in the R3 definition above and therefore not recorded until such times as the next inspection if they meet intervention levels as detailed above. These are not included in the Road Network and Condition Statistics report.

The surface defect figures in the Road Network and Condition Statistics report, cover defects that are classified as either R 1, R 2 or R 3. Users should also note that surface defects are only included in this report following an inspection by DfI.

An inbuilt script is run within the RMCS system to prioritise the repairs required. Work orders are then issued to the operational maintenance team and/or outside contractors and when these jobs are completed, the work orders are returned to the relevant maintenance office and the surface defects repaired are recorded in the system. It should be noted that lower priority surface defects may be recorded for future planning purposes and therefore may not be instructed for repair.

The data extracted for the production of official statistics are the surface defects instructed and repaired within the financial year. Note that surfaced defects repaired in one year may have been reported prior to this financial year. Also due to funding and resource constraints, throughout the year there is a backlog of instructed defects incomplete; the statistics in the report currently focus on the surface defects instructed and repaired during each financial year.

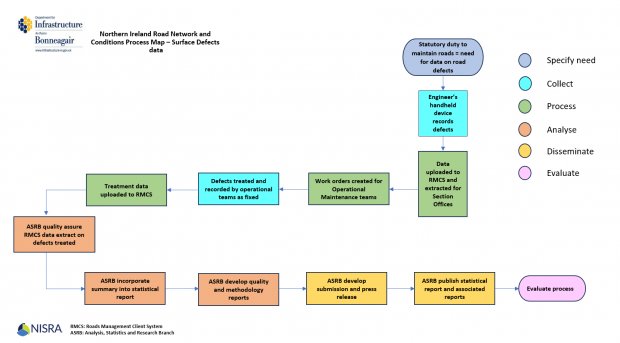

A process map showing the flow of data on road surface defects repaired/treated from collection to dissemination is available below and on the DfI website.

Further information relating to the quality of surface defect data from RMCS is available from the Northern Ireland Road Network and Condition - Quality Assurance of Administrative Data Report.

Road Expenditure (Account NI)

Data on public expenditure on NI Roads are recorded by DfI staff on the Account NI system. End of year information on public expenditure is used to produce the annual accounts which are approved and audited by the NIAO.

Public expenditure data is classified according to the following categories: -

- New construction and improvement

- Structural Maintenance – Capital (includes resurfacing and reconstruction, asphalt patching, surface dressing, capital investment in drainage infrastructure and capital investment in the structural stability of embankments)

- Structural Maintenance – Resource (includes patching of carriageway and footways)

- Highway Structures (includes maintenance of bridges and retaining walls)

- Routine Maintenance (includes environmental maintenance (grass cutting, weed control, tree maintenance etc.), gully emptying and cleaning, fencing and minor repairs to embankments, cuttings and verges)

- Traffic Maintenance (includes road markings, safety fences & guardrails, energy to illuminate traffic signs and signals and maintenance of traffic signs and signals)

- Winter Maintenance (includes salting and snow clearance)

- Public Lighting (includes maintenance and energy)

- Park & Ride/Share Sites (does not include the cost of Decriminalised Parking Enforcement)

- Other (expenditure which is not detailed in the categories above such as some Admin overheads, Liability costs, DBFO Private Public Partnership charges, Road Drainage charge from NIW, contractual costs associated with Enforcement of Parking and Moving Traffic offences, purchases of Fleet, IT and other Plant Property and Equipment (PPE) and Active Travel Grants (e.g. Greenway Grants))

ASRB have also carried out a separate quality assurance of administrative data (QAAD) assessment on the Account NI system. The QAAD is available on the DfI website.

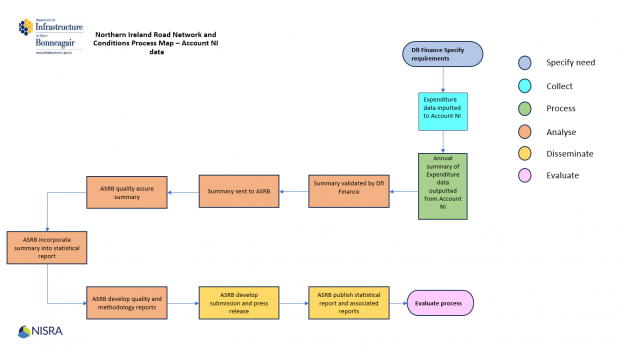

A process map showing the flow of Account NI data from collection to dissemination is available below and on the DfI website.

Further information relating to the quality of expenditure data from Account NI is available from the Northern Ireland Road Network and Condition - Quality Assurance of Administrative Data Report

Useful Links

Links to websites with data for the rest of the UK

This publication covers the Northern Ireland road network. Links to publications for England Scotland and Wales can be found below: -

Scottish Transport Statistics (Chapter 4 – Road Network)

Statistics | Transport Scotland

Welsh Road Lengths and Conditions

Road lengths and conditions | GOV.WALES

English Road Condition

Links to other relevant data or websites

Carriageway Surface Defects - Datasets - Open Data NI (note however that the data published in the Road Length and Condition report is surface only defect data and only relates to carriageways, hard shoulders and laybys. Surface defects do not count other defects such as white lining, deflective signage etc. whereas the data held within the Open Data NI portal records data on all of the above, while also having data on footways and maintained laneways, and also recording a wider range of all defect types).

Transport Infrastructure Ireland – maintenance and network of Roads in Ireland

Technical guide for English Road Condition report

Links to main report and Background Quality Report (BQR)

The Northern Ireland Road Network and Condition report is available on the DfI website along with a Background Quality Report (BQR).

Maps of the Road Network in Northern Ireland by Class of Road

Glossary of Technical Terms

Account NI - Account NI process invoices for DfI and other NI Civil Service Departments

ASRB – Analysis, Statistics and Research Branch

Deflectograph surveys - carried out by a vehicle that measures the deflections of the roads surface under defined loading

DfI - Department for Infrastructure

GIS - Geographic Information System

IL – Investigatory level

LGD - Local Government District

PMS - Pavement Management System

Roads: -

- Motorway - Normally a dual carriageway road designed for higher speed traffic with designated places for joining and leaving.

- Trunk Road Network (TRN) - Motorways and all purpose trunk roads owned by DfI who have responsibility for maintenance and operation. These are strategic roads with a high proportion of long distance traffic although some trunk roads may also have lengths, with the same number, designated as an ‘A’ principal road, where traffic is predominantly local in nature.

- A roads - major roads intended to provide large-scale transport links within or between areas.

- B roads - roads intended to connect different areas, and to feed traffic between A roads and smaller roads on the network.

- C roads - smaller roads intended to connect together unclassified roads with A and B roads.

- Unclassified roads - local roads intended for local traffic.

RCI - Road Condition Indicator

RMCS - Road Maintenance Client System

SCANNER - Surface Condition Assessment for the National Network of Roads

Further information

For further information relating to the technical aspects of the ‘Northern Ireland Road Network and Conditions’ report, please contact ASRB@nisra.gov.uk .

Last updated: December 2023